If the actual amount exceeds the standard amount, the variance is unfavorable (U) indicating they used or paid more than the standard amount, which is unfavorable. To illustrate standard costs variance analysis for direct materials, refer to the data for NoTuggins in Exhibit 8-1 above. The direct material standards for one unit of NoTuggins are 4.2 feet of flat nylon cord that costs $0.50 per foot for a total direct material cost per unit of $2.10.

Practice Video Problem 8-3: Computing manufacturing overhead variances LO4

When discussing variable manufacturing overhead, price is referred to as rate, and quantity is referred to as efficiency. These standards are compared to the actual quantities used and the actual rate paid for variable manufacturing overhead using the same processes applied in previous sections to analyze direct materials and direct labor. Any variance between the standard costs allowed and the actual costs incurred is caused by a difference in efficiency or a difference in rate. The total variance for variable manufacturing overhead is separated into the variable manufacturing overhead efficiency variance and the variable manufacturing overhead rate variance.

Direct Labor Efficiency Variance

This data prompts a focused investigation into production bottlenecks, enabling corrective action. Addressing these discrepancies enhances resource utilization, productivity, and cost control, which is vital for optimizing operations and ensuring the efficient use of labor within a business or manufacturing setting. Note that both approaches—the direct labor efficiency variancecalculation and the alternative calculation—yield the sameresult.

Ask a Financial Professional Any Question

An important factor in measuring efficiency variance is the development of a set of realistic assumptions surrounding the theoretical amount of inputs that should be required. If the actual amount of inputs used exceeds the amount theoretically required, there is a negative efficiency variance. Through virtual bookkeeping, one can ensure that business owners are well prepared for their taxes. The bookkeeping service with single entry bookkeeping, double entrybookkeeping, or even accrual bookkeeping makes sure that the transactions are efficiently recorded.

- All standard cost variances are computed using the actual production quantity.

- Thus, it is extremely challenging to establish a standard that you can effectively compare to actual results due to the large number of factors involved.

- Total direct material costs per the standard amounts allowed are the total standard quantity of 630,000 ft. times the standard price per foot of $0.50 equals $315,000.

- We have demonstrated how important it is for managers to beaware not only of the cost of labor, but also of the differencesbetween budgeted labor costs and actual labor costs.

- In particular, she ran out of the alloy used to make Lastlock and was forced to purchase a lower quality batch from a different supplier.

The standard quantity and price to make one unit of Lastlock are provided below. The standard number of hours is the industrial engineers’ best guess as to the ideal rate at which the production team can produce things. Based on estimates about the setup time for a production run, the availability of materials and machine capacity, employee skill levels, the length of a production run, and other factors, this number can vary significantly. Thus, it is extremely challenging to establish a standard that you can effectively compare to actual results due to the large number of factors involved. The labor efficiency variance assesses the capacity to use labor in accordance with expectations.

What is your current financial priority?

If direct materials is the cause of adverse variance, then purchase manager should bear the responsibility for his negligence in acquiring the right materials for his factory. Labor efficiency variance is the difference between the time we plan and the actual time spent in production. It is the difference between the actual hours spent and the budgeted hour that the company expects to take accountability vs responsibility to produce a certain level of output. The actual time can be shorter or longer due to various reasons, so it will create a favorable and unfavorable variance. This result is interpreted as the organization saved $15,000 in direct materials costs by using less direct material per unit than they planned. It is important to remember that standards are the planned or projected amounts.

Since she paid less for the material and labor, Patty assumed that at the end of the period overall manufacturing costs would be lower than projected. However, manufacturing costs were higher than expected at the end of the period. Accordingly, Patty decided to perform a standard cost variance analysis on the variable manufacturing costs. With either of these formulas, the actual hours worked refers to the actual number of hours used at the actual production output.

Brad spent $9,000 more on variable manufacturing overhead than he projected. Refer to the total direct labor variance in the top section of the template. Total standard quantity is calculated as standard quantity per unit times actual production or 0.25 direct labor hours per unit times 150,000 units produced equals 37,500 direct labor hours.

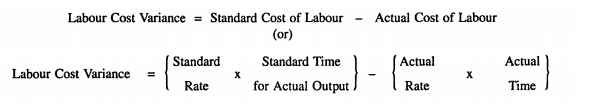

Suppose, for example, the standard time to manufacture a product is one hour but the product is completed in 1.15 hours, the variance in hours would be 0.15 hours – unfavorable. If the direct labor cost is $6.00 per hour, the variance in dollars would be $0.90 (0.15 hours × $6.00). For proper financial measurement, the variance is normally expressed in dollars rather than hours. Labor efficiency variance, also referred to as labor time variance, constitutes a segment of the broader labor cost variance. This variance emerges from the disparity between the anticipated standard labor hours and the actual hours expended.

As a result of this unfavorable outcome information, the company may consider retraining its workers, changing the production process to be more efficient, or increasing prices to cover labor costs. In this case, the actual hours worked per box are \(0.20\), the standard hours per box are \(0.10\), and the standard rate per hour is \(\$8.00\). The flexible budget is comparedto actual costs, and the difference is shown in the form of twovariances. It is defined as the differencebetween the actual number of direct labor hours worked and budgeteddirect labor hours that should have been worked based on thestandards.